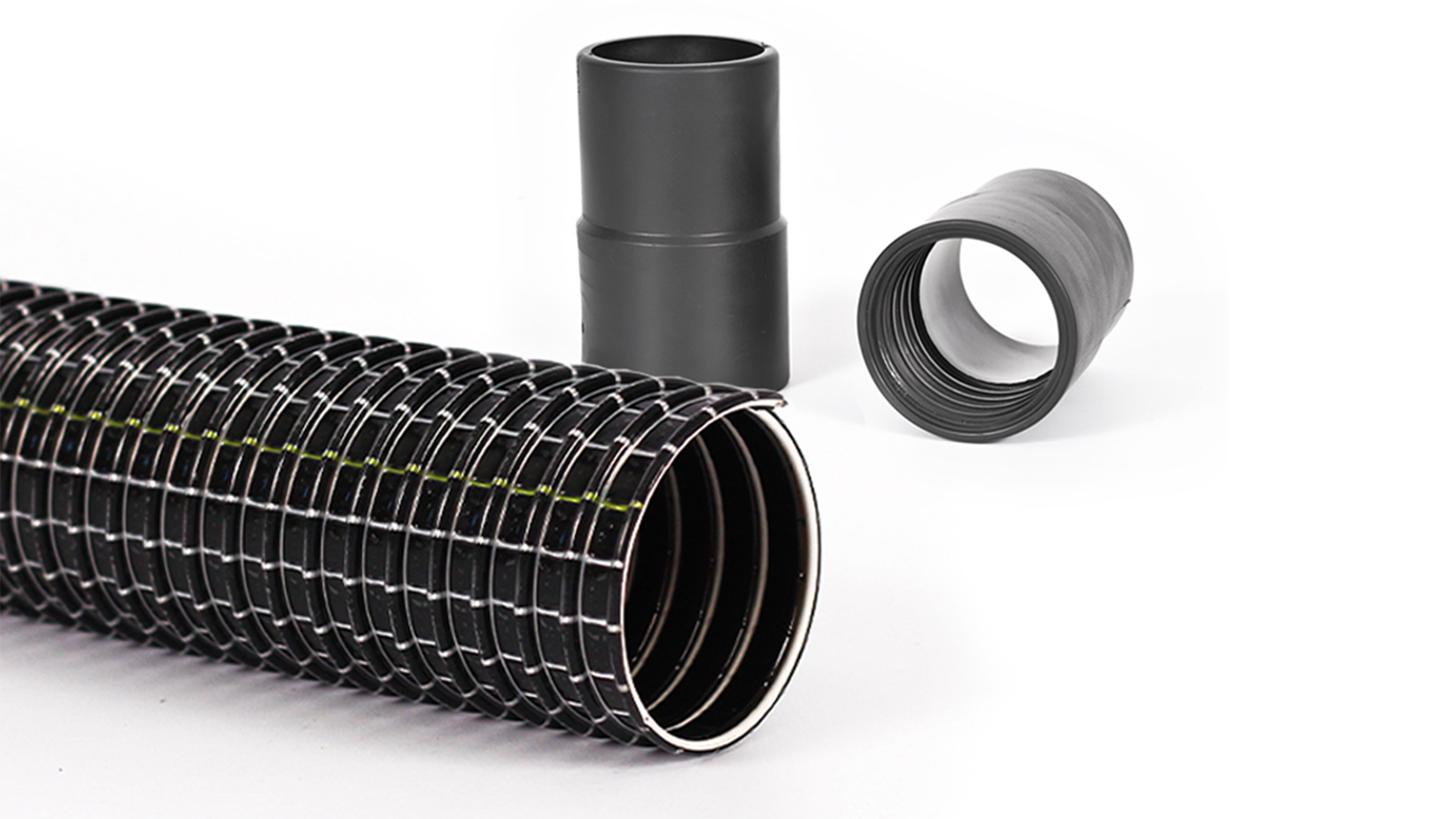

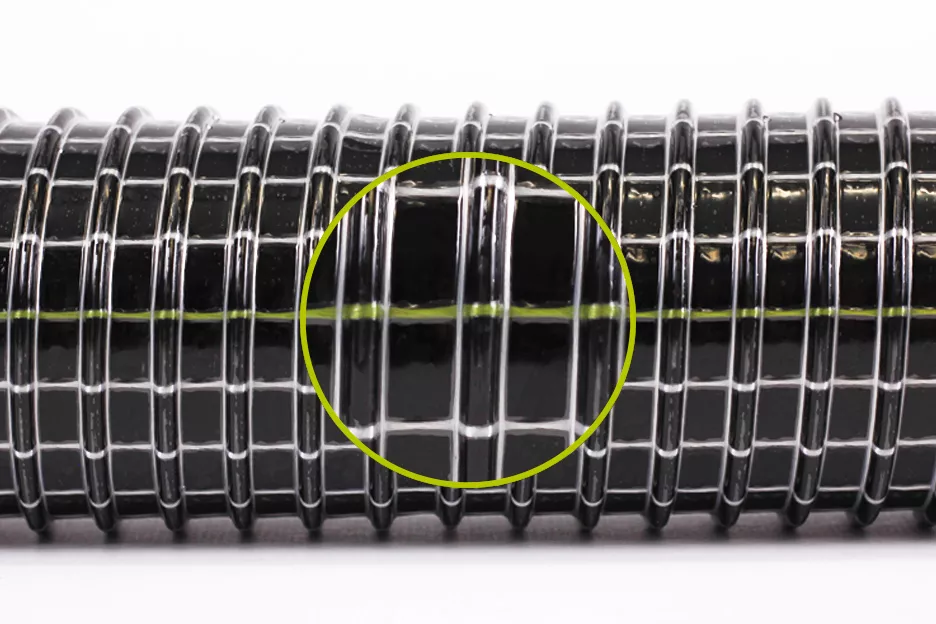

Industrial vacuum cleaner

Suction hose for washing vacuum cleaner Ø32mm | L: 2.4m

€46.97*

Content: 2.4 meters (€19.57* / 1 meter)

What our customers say

Your advantages with Primaflex

How do I properly care for and maintain my industrial vacuum hose?

Proper care and maintenance of your industrial vacuum hose can help extend its life and ensure optimum performance. Clean the hose regularly to prevent a buildup of dirt and debris that could affect suction performance. Also check the hose for signs of damage, such as cracks, cuts, or abrasion, and replace the hose as needed. Make sure the hose is properly connected to the vacuum and that all seals and connections are intact.

What size hose do I need for my industrial vacuum?

The required hose size for your industrial vacuum depends on several factors, including the size of the vacuum, the type and amount of material to be removed, and the specific requirements of your application. In general, larger industrial vacuums require larger hoses to provide adequate suction. It is important to follow the manufacturer's instructions or the advice of a professional to ensure you select the correct size.