Frequently asked questions

Whether you want to learn more about the different areas of application, specifications or the proper care and handling of our products, you will find sound knowledge directly from the manufacturer in our FAQs.

We supply more than just hoses. Here are the answers you need.

At Primaflex, we know that selecting the right hose can be critical to the successful operation of your systems and equipment. That's why we've made an effort to create a comprehensive and detailed collection of answers to the most frequently asked questions about our hoses & their applications. Our FAQs cover a wide range of topics - from technical specifications and areas of application to the proper care and handling of our products.

Each question and answer is carefully worded to provide a clear and understandable explanation. We have made every effort to ask the questions from our customers' perspective to ensure that we address the concerns and issues that are most important to you.

However, if you have a specific question that is not answered here, please do not hesitate to contact us. Our team of experts is always available to help you with any concerns and ensure that you receive the best possible service.

General questions about technical hoses & their applications

Please note that our hoses are not expandable and precise sizing is critical. Use appropriate precision tools for sizing to achieve accurate measurement results.

Durability: PU hoses are generally more durable and abrasion resistant than PVC hoses.

Chemical resistance: PVC hoses are generally more resistant to chemicals than PU hoses

Temperature resistance: Both PVC and PU hoses are resistant to high temperatures, but PU hoses can withstand higher temperatures for longer periods of time.

Cost: PVC hoses are generally less expensive than PU hoses.

Composition: Silicone hoses are made from silicone, while neoprene hoses are made from neoprene, a type of synthetic rubber.

Durability: Silicone hoses are generally more durable and wear resistant than neoprene hoses.

Chemical Resistance: Both silicone and neoprene hoses are resistant to a variety of chemicals, but silicone hoses have better overall chemical resistance.

Temperature Resistance: Both silicone and neoprene hoses are resistant to high temperatures, but silicone hoses can withstand higher temperatures for longer periods of time.

Cost: Silicone hoses are generally more expensive than neoprene hoses.

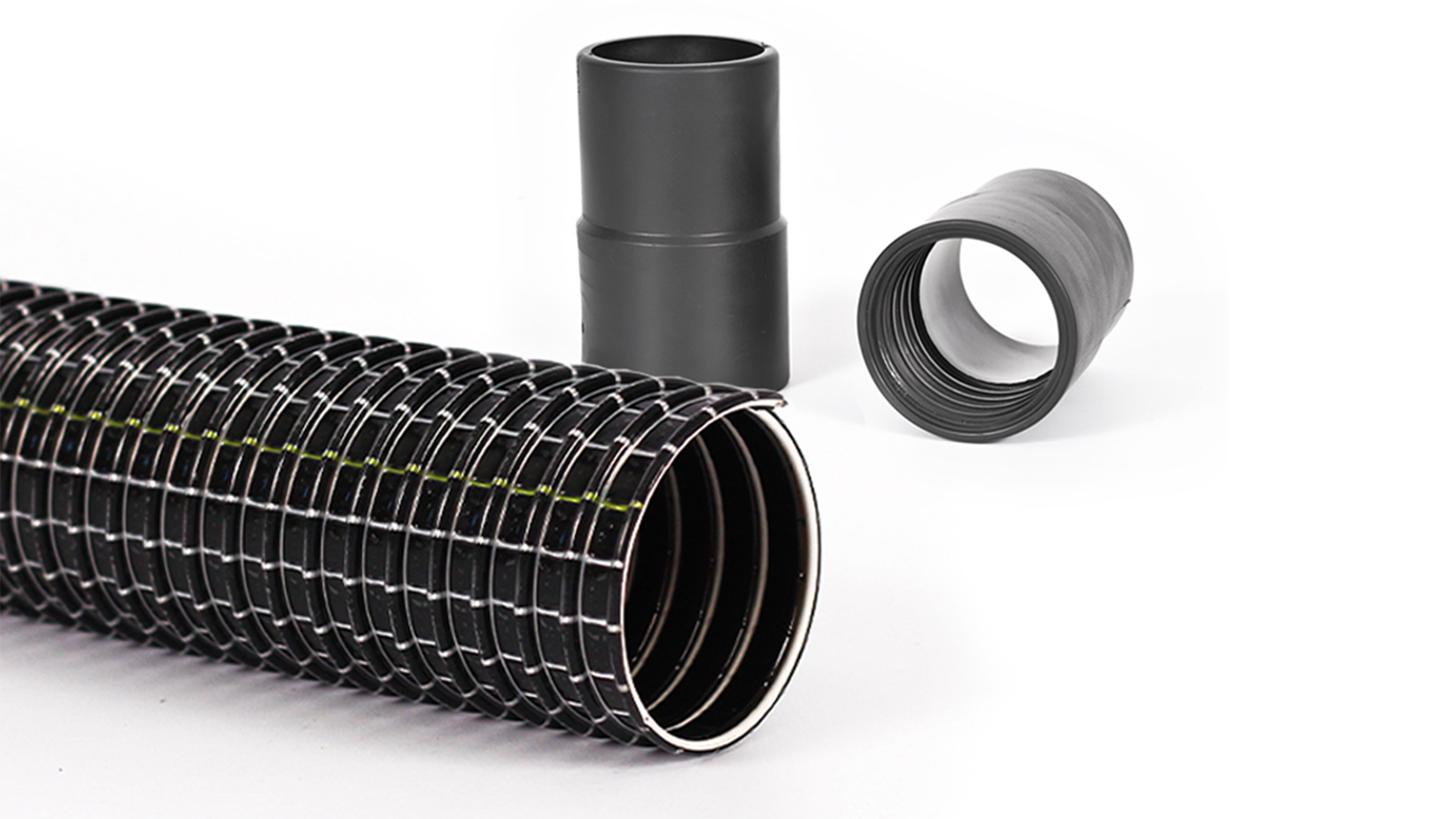

Questions about suction hoses & their applications

Durability: PU hoses are generally more durable and abrasion resistant than PVC hoses.

Chemical resistance: PVC hoses are generally more resistant to chemicals than PU hoses

Temperature resistance: Both PVC and PU hoses are resistant to high temperatures, but PU hoses can withstand higher temperatures for longer periods of time.

Cost: PVC hoses are generally less expensive than PU hoses.

Questions about PVC hoses & their applications

Questions about hot air hoses & their applications

Construction heaters are usually used to enable construction work during cold months or in cold climates. They provide a comfortable working temperature and prevent materials from freezing. Construction heaters typically use a heat source type, such as electricity, gas, or oil, to heat air. This heated air is then directed through special warm air hoses to the area to be heated.

When selecting a hot air hose for construction heating, several factors should be considered. These include the operating temperature, the length and diameter of the hose, the material resistance (e.g. to temperature and/or other conditions) and the flexibility of the hose.

Installation of construction heating hoses should always be carried out according to the manufacturer's instructions. Typically, the hoses are connected to the heater and then positioned to effectively distribute the heated air. Hose maintenance includes regular inspection for damage or wear and thorough cleaning to remove debris and ensure efficient airflow.

Yes, our warm air hoses are available in different versions to cover a wide range of applications, from air conditioning and heating to air conditioning and heating to use in particularly harsh conditions. conditions.

Yes, we offer color-coordinated warm air hoses that can perfectly perfectly match your event or project. Please contact us for more information.

Yes, Our warm air hoses are designed for different temperature ranges. designed. Some models are even suitable for temperatures up to +150°C.