Woodworking

What our customers say

Your advantages with Primaflex

How do I properly care for and maintain my woodworking hoses?

Proper care and maintenance of your woodworking hoses can extend their life and ensure their effectiveness. Clean the hoses regularly to prevent a buildup of dust and chips that could restrict airflow and reduce the efficiency of the extraction system. Also check the hoses regularly for signs of wear or damage and replace them as needed.

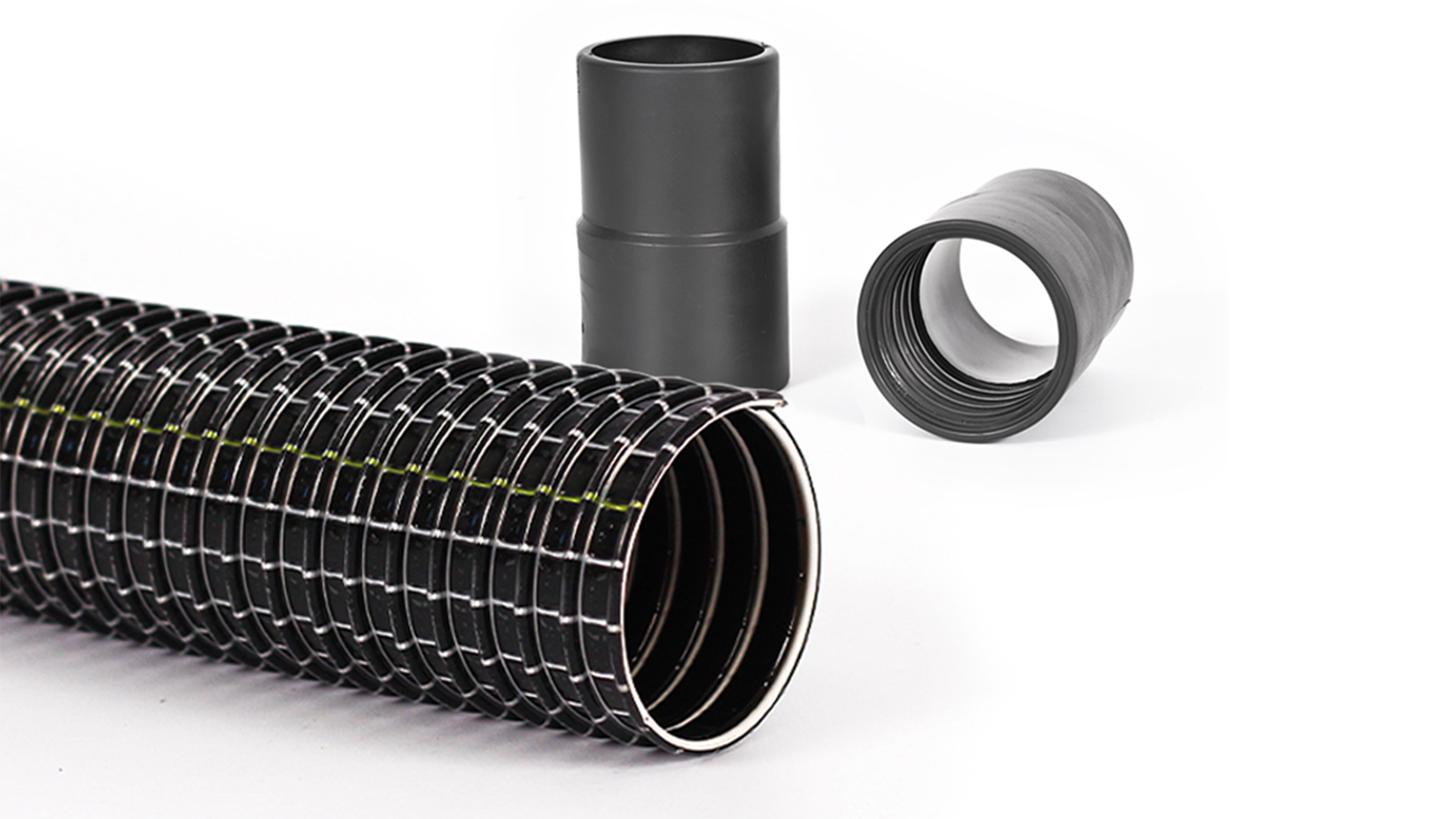

What factors should be considered when choosing a hose for woodworking?

When selecting a hose for woodworking, consider the size and shape of the hose, the type of material to be absorbed (fine dust or larger chips), the length of the hose, the flexibility needed, and the hose's resistance to abrasion. Some hoses are also anti-static, which can be important when working with wood dust to prevent the accumulation of static electricity.

How important is dust extraction in woodworking?

Dust extraction in woodworking is critical for several reasons. First, it contributes to workplace safety by reducing the amount of wood dust that becomes airborne and could be inhaled. Wood dust can cause health problems, including respiratory problems and allergic reactions. Second, effective dust collection helps keep work areas clean, which in turn improves the quality of manufactured products. Finally, reducing the amount of wood dust can help reduce the risk of fire or explosion, as wood dust can be combustible in high concentrations.